Sweden’s largest fossil-free hydrogen facility is now being built with the goal of greatly reducing CO2 emissions, developing local industrial hydrogen production, and taking the first step towards a future hydrogen infrastructure for the transport sector. Ovako is starting a collaboration with the Volvo Group, Hitachi ABB Power Grids Sweden, H2 Green Steel and Nel Hydrogen to invest in hydrogen production in Hofors.

The new hydrogen plant in Hofors will make Ovako the first in the world to heat steel with hydrogen prior to rolling, and is the next major step towards climate-neutral steel production. The technical solution will also enable large-scale and cost-effective production of hydrogen for applications like fossil-free freight using fuel-cell trucks. With installations at multiple locations, this could enable a network with locally produced fossil-free hydrogen available for the transport sector.

Ovako is now initiating cooperation with several key players in Swedish and Norwegian industry. The initiative is also supported by the Swedish Energy Agency, with the shared goal of establishing industry-wide use of fossil-free hydrogen, expanding awareness of the potential of this fuel, and achieving cost-effective production. A filling station for hydrogen-powered heavy vehicles is intended to be built beside the hydrogen plant.

“It is important that we cooperate across industrial boundaries and invest in solutions that provide substantial and rapid climate benefits. Since 2015, Ovako has reduced its CO2 emissions by 54%, and we will now be the first steel company to show that it is possible to eliminate CO2 for heating steel before rolling, and get even closer to climate-neutral production,” says Marcus Hedblom, President and CEO Ovako.

“The transport sector is undergoing a paradigm shift, and green hydrogen will be one of the most important energy vectors in the transport industry for long-haul and heavy freight. Decentralized hydrogen production in the steel industry fits very well with the transport industry’s need for fossil-free fuel. This technological solution is scalable because it can be used by the steel industry in large parts of the world. Working in partnership with other industries to be involved in the entire value chain around our transport solutions is essential,” says Lars Stenqvist, Chief Technology Officer Volvo Group.

“Where direct electrification is not possible, green hydrogen is one of the complementary energy carriers which can support the energy transition towards a carbon-neutral future. This exciting collaboration will test new value chains, and we look forward to acquiring knowledge about how an electrolysis plant can interact with the existing electricity network and become an important resource for its stability,” says Jenny Larsson, Managing Director, Hitachi ABB Power Grids Sweden.

“H2 Green Steel wants to accelerate the transition to fossil-free production in heavy industry throughout Europe and the rest of the world. By replacing fossil fuels, green hydrogen will be critical to the transition of most industrial processes. Together with Ovako, we are now able to test the production of fossil-free hydrogen and assess how this fuel can best be used to achieve and control the high temperatures required to produce high-quality steel. This knowledge will serve as important input into our own large-scale hydrogen production starting in Boden in 2024,” says Maria Persson Gulda, Chief Technology Officer at H2 Green Steel.

“We are thrilled to participate in this exiting project together with great leading partners. We will work collaboratively together to make this project a success, based on the joint learnings we will standardize the overall solution and ensure that this can be replicated in different locations all across Europe,” says Jon André Løkke, CEO of Nel Hydrogen.

“We see this investment in hydrogen at Ovako as a strategically important effort in the transition to a more fossil-free society. Our hope is that the solution can be expanded throughout the steel industry and to other industries that currently use fossil fuels for heating steel,” says Klara Helstad, head of the sustainable industry unit at the Swedish Energy Agency.

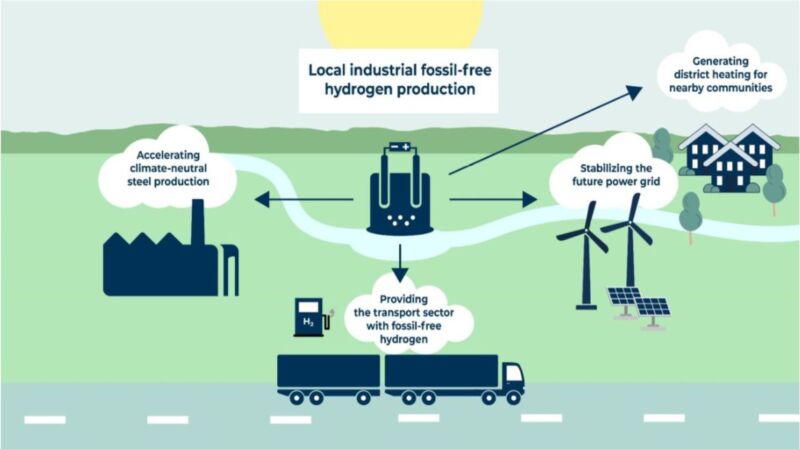

This technical solution provides high-temperature processes in steel production with fossil-free hydrogen and oxygen, and thus replaces fossil fuels. With a greater need for oxygen than hydrogen in the steel industry, there are also good opportunities for cost-effective and large- scale use of hydrogen in other areas, such as fossil-free freight with fuel cell trucks. The solution can be used flexibly and can therefore contribute to improved electricity grid stability, which in turn allows for a higher proportion of renewable energy sources. Furthermore, the residual heat can be utilized in district heating networks.